When thinking about solar panels, the word reliability is the one that comes to mind. PV modules are durable, can withstand a hurricane and serve their owners diligently for more than 25 years. Looks like we can hardly have any problems with solar panels, doesn't it? Far from it!

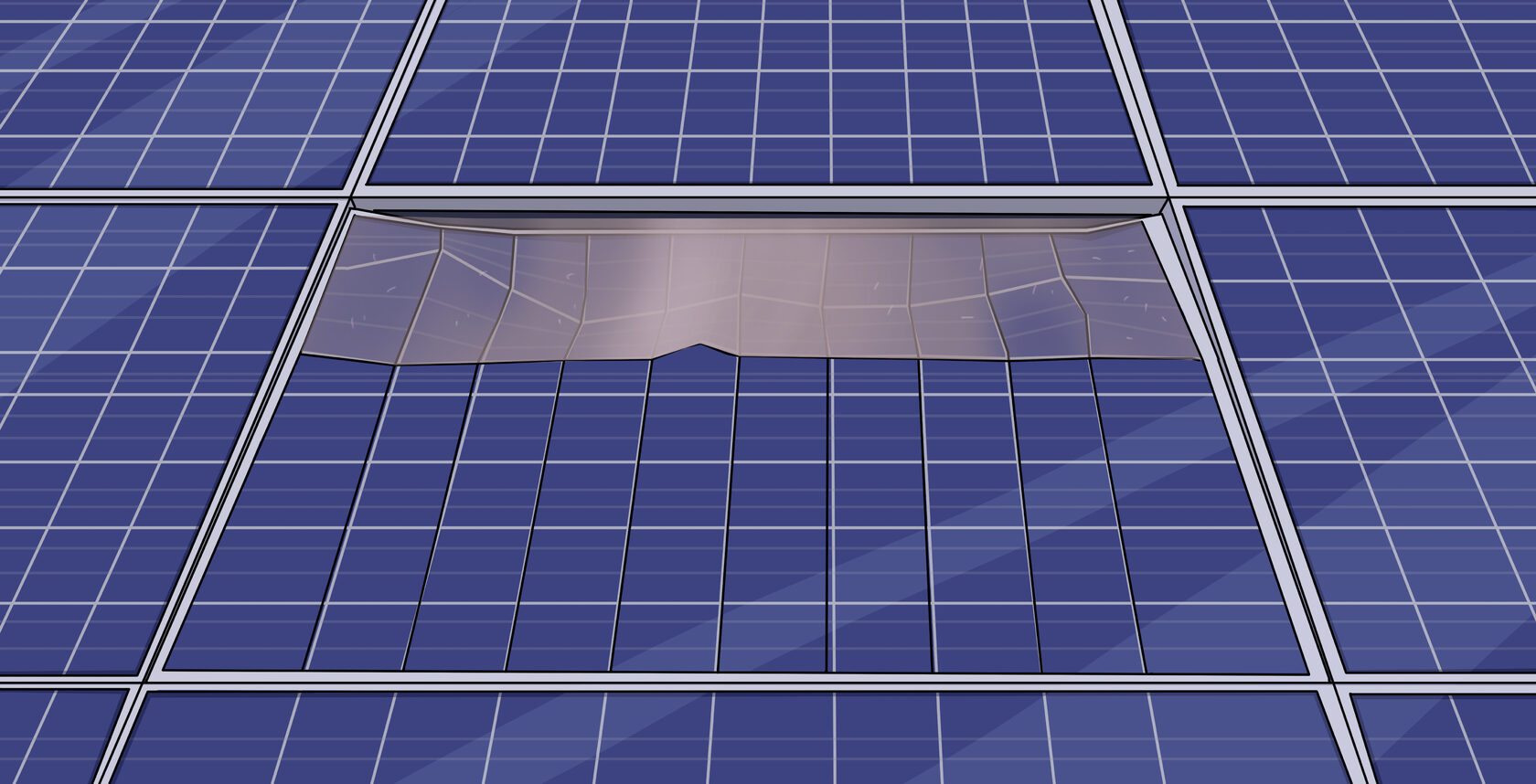

Delamination lets the air and moisture into the panel

To keep solar cells safe, manufacturers protect them with a layer of tempered glass and the plastic back sheet. These layers are sealed tightly to prevent the internal corrosion. However, sometimes they separate which is called the delamination of solar panels. It leads to corrosion and eventually to the failure of a PV module.

The reasons for delamination can be different: bad workmanship, poor manufacturing, high temperatures. Delamination often takes place in tropical climates, and semi-flex panels are especially vulnerable.

Usually the process starts at one angle or a side of the panel and then spreads across the PV module. You can detect the start of delamination by bubbles and creases on the plastic rear surface. Some owners try using duct tape and sealant to slow the process down, but such a panel isn't going to last long. So, once you've seen any of the signs of delamination, contact your installer immediately.

Having trouble with solar panels?

Fill out form and compare offers from solar professionals

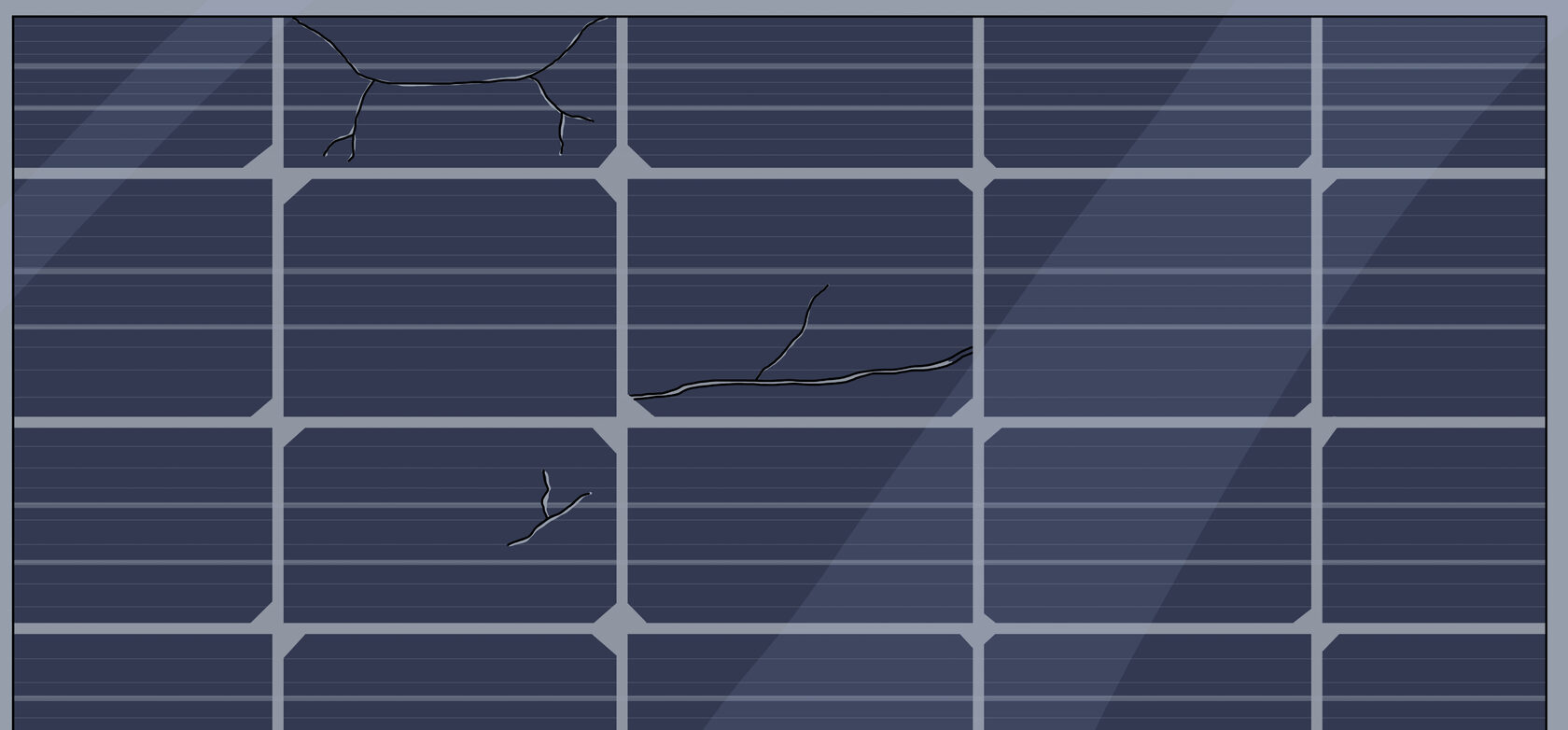

Get quotesMicrocracks appear after careless delivery

Microcracks are another type of solar panel problem. They typically occur during solar cell manufacturing and module assembling. Unfortunately for the owners of solar panels, microcracks are hard to detect with the naked eye. That is why we recommend going for top solar manufacturers, like Canadian Solar, Trina, Panasonic etc., as their production process always includes electroluminescence testing. It allows checking every module for microcracks before shipping.

Another way microcracks may appear is careless shipping or installation. Preventing cracks is easy when you pick up panels yourself from a warehouse, vertically stacked or wrapped in blankets or foam. Try not to drop your panels or step on them during the installation.

Read also:

Remember, however, that no matter how carefully you handle PV modules, some of them are just more susceptible to cracking than others. The least crack-prone option would be a monocrystalline module with half-cut solar cells and the maximum number of busbars. It is explained by the material properties and smaller cell surface that can be potentially inactive.

Sometimes microcracks have almost no consequences at all. If they don’t cause electrical separation inside a PV module, then the efficiency might drop by only around 2.5%. If electrical separation does occur, it makes a cell or a sector of a solar panel inactive and can even lead to hot spots.

Microcracks are the main reason why going for the second-hand solar panels is usually not the best idea. You likely won't be able to see the cracks when inspecting someone else's panels without special equipment - and who knows what they've been through.

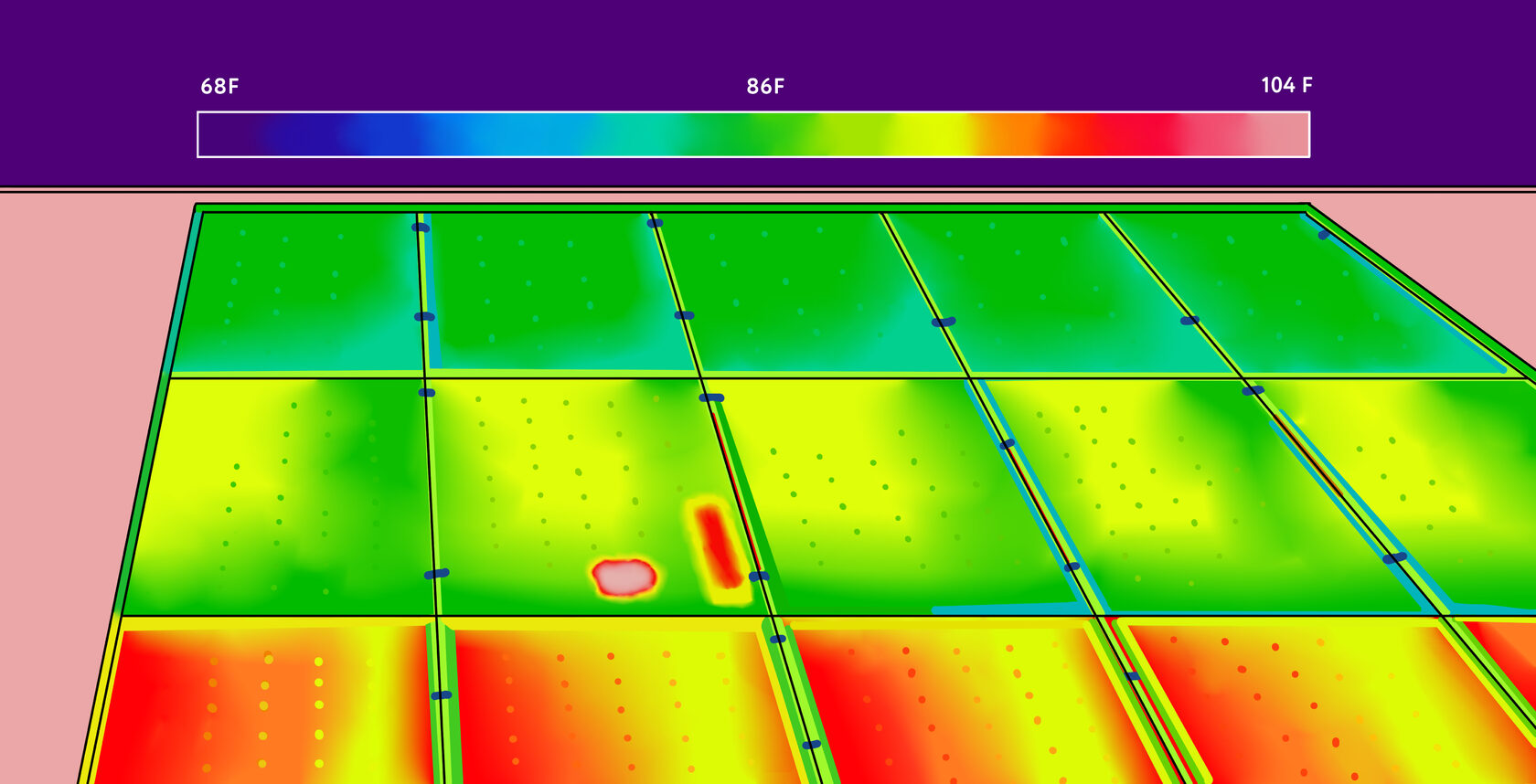

Hot spots shorten the lifespan of a panel

Hot spots can stem from overshadowing, dirt or microcracks. When the sunlight hits solar cells, it is supposed to be converted into electricity. However, if the resistance of one solar cell rises, this part of the panel heats up. This is the hot spot – overproportional heating of one cell compared to the others.

You can detect an emerging hot spot with an infrared camera only. Eventually, hot spots in solar panels become visible to the eye: the problematic cell becomes brownish.

Hot spots lead to a faster solar panel degradation and can even start a fire on your roof. To avoid that, clean your panels from dirt every now and then. Before the installation, carefully pick a place without any shade. If some shading is unavoidable, opt for panels with a high shading tolerance and bypass diodes, like Panasonic HIT 330W or REC 365W Alpha.

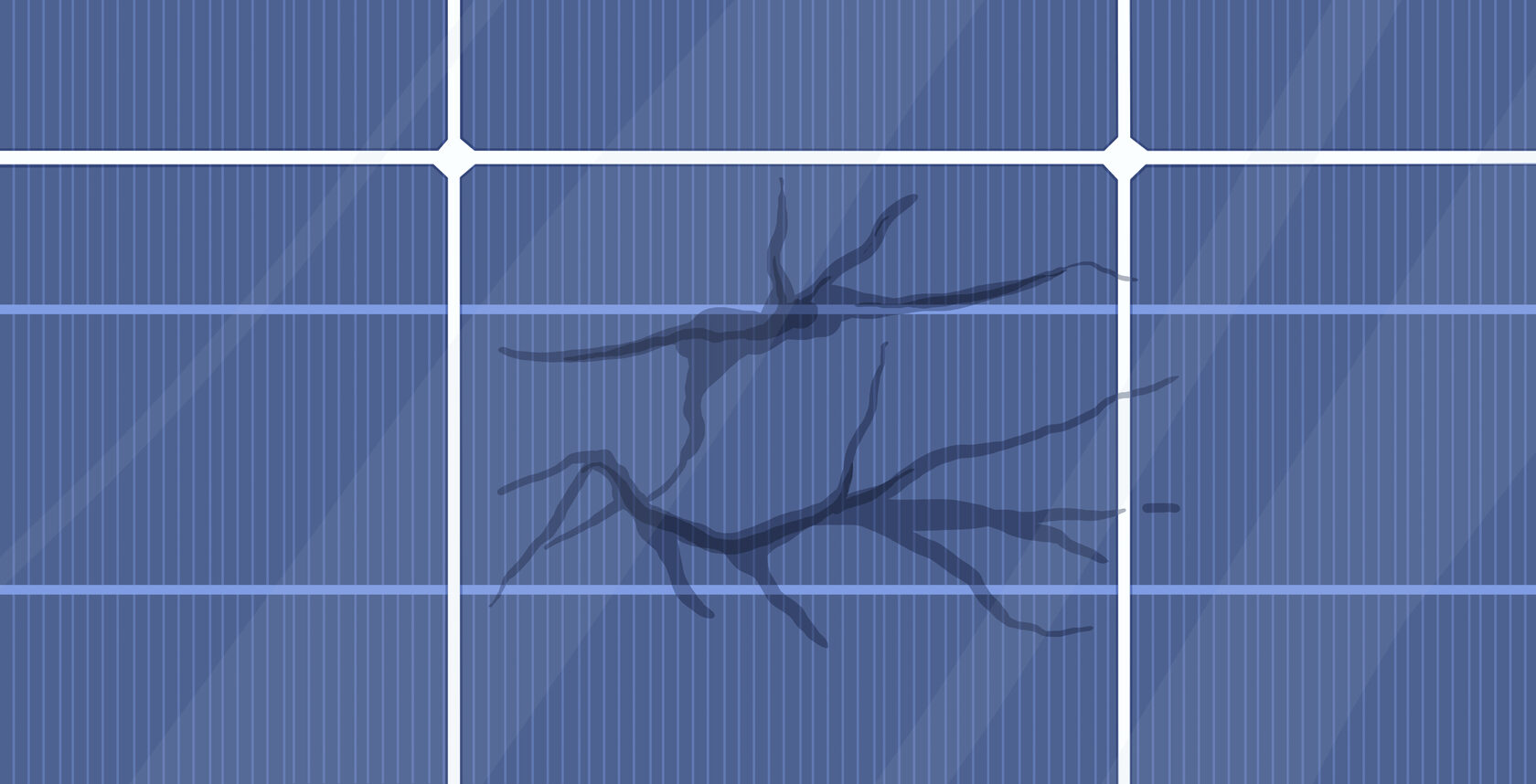

Snail trails is a common problem of low-quality panels

Snail trails or worm marks are short thin dark lines on the surface of a solar panel. Just to clear it up: they have nothing to do with actual snails. They may appear several years after the installation along the edges and, most importantly, where microcracks are located.

If you've discovered snail trails on solar panels, it usually means that the PV modules are of a low quality. Snail trails are the products of oxidation, often caused by microscopic cracks in the panel or defective front metallization silver paste, which is used in the solar cell manufacturing process.

Luckily, snail trails by themselves only impact the appearance of a module and don't have any significant impact on its efficiency.

Potential induced degradation can lower the output by a third

Potential induced degradation or PID is a result of so-called stray currents, which appear when the module's voltage doesn't match the earthing. The effects of PID are worsened by high humidity, high temperatures and high voltages of a system, so it can lower the power output of a PV installation by a third. Potential induced degradation in solar modules almost never happens if you use microinverters: they don't allow the voltage to go too high.

There are no visual signs of potential induced degradation of solar cells and panels, but it can be detected with an infrared camera, electroluminance or photoluminescence testing. So, if you suspect that PID might take place – for example, you get much less energy than expected – invite an expert for an inspection. PID isn't a rare occurrence: in 2013, solar panels of 19 out of 23 global solar manufacturers were susceptible to PID, according to ISE Fraunhofer.

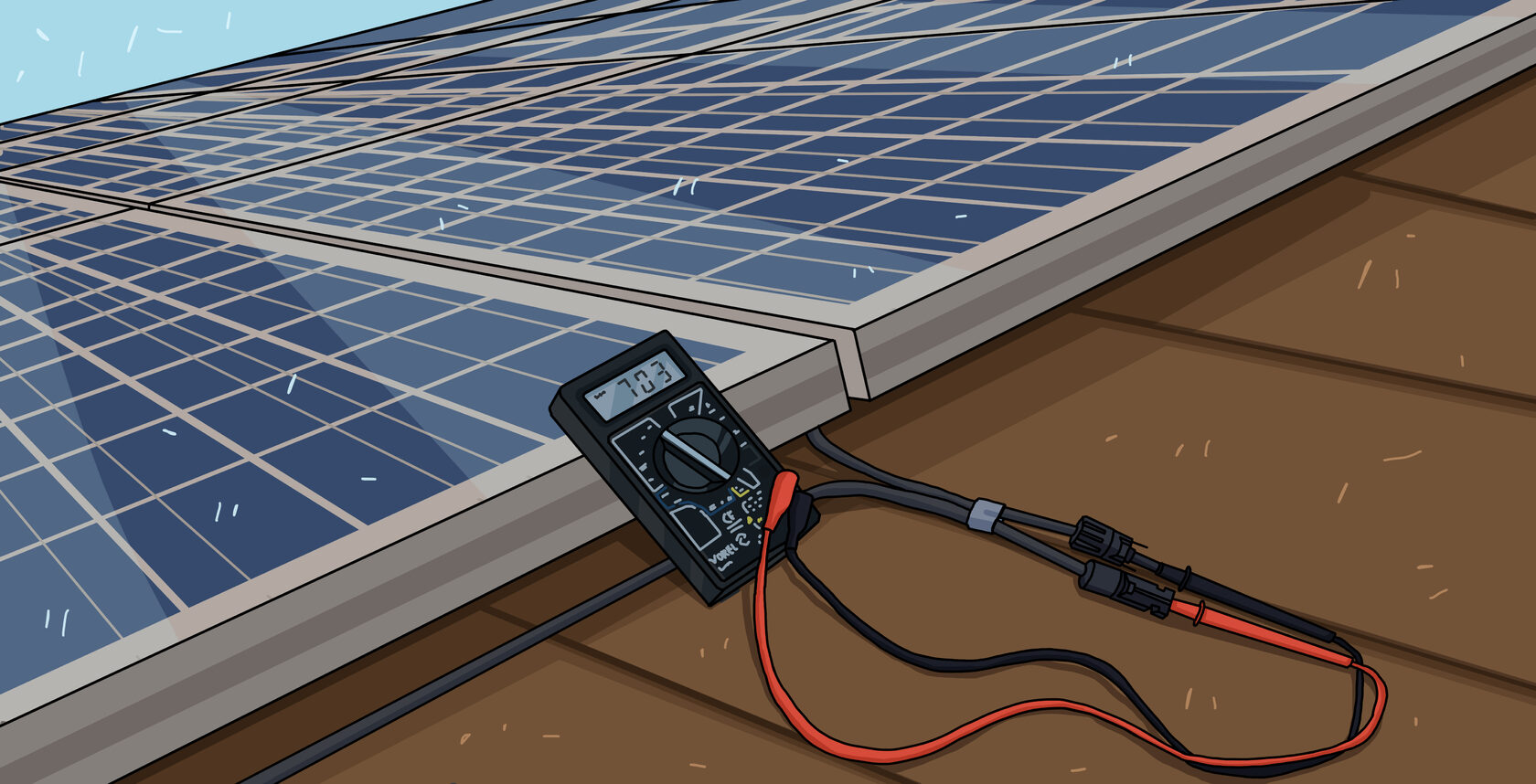

Electrical issues: Check your wires!

Read also

Solar wire exposed: types and sizes

Solar wire exposed: types and sizesA large share of issues with solar power stem from wiring problems. A loose connection can lead to corrosion, energy losses and shorter lifespan of a system. If you've connected solar panels in series, problems with wiring may lead to the loss of power in the whole string. Careless connection of panels can create an open circuit where you're likely to lose a substantial amount of energy. It is recommended not to try to deal with electrical issues of solar panels yourself – better call a certified electrician for help.

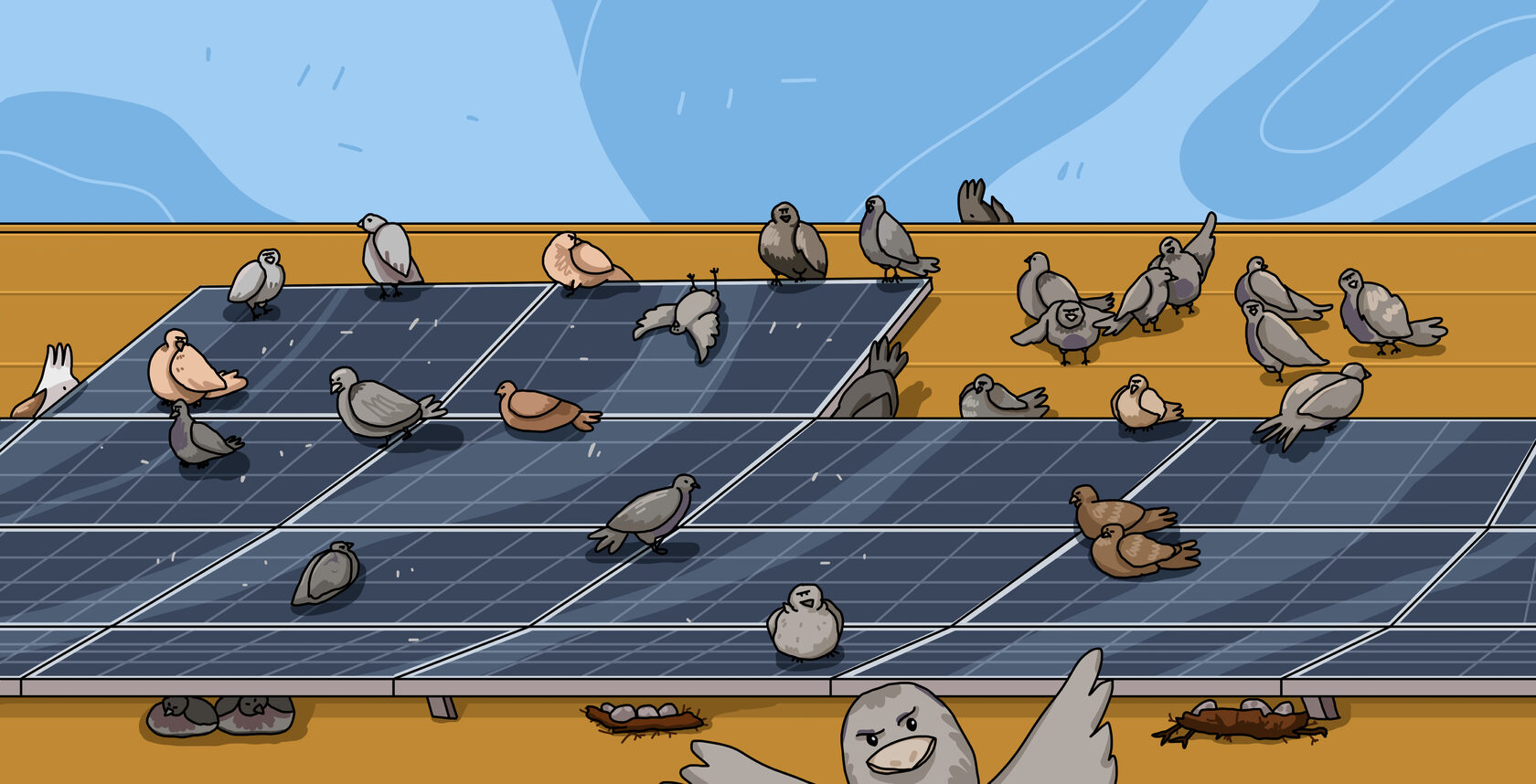

Birds turn your solar panels into their nests

Surprisingly, solar panels are quite popular among birds and squirrels. They find the space between PV modules and roof to be perfect for their nests. It's needless to say that animals can effectively mess up the wiring of solar panels, damage important parts and, finally, bird droppings are hard to remove. If you find birds nesting under solar panels – call critter guards, no exceptions. Some companies, like BirdBarrier, offer metal nets that minimize the chance that some pigeons would settle down under your panel. Don't get us wrong, we love animals, but the solar panel protection comes first for us.

Solar panels endure, persevere and keep on working

If you haven't purchased solar panels for yourself yet, don't let this list discourage you. The problems mentioned here might or might not happen to you, and most of them aren't fatal for a solar installation. Solar panels are a long-time reliable investment: the average life of solar panels exceeds 25 years. They can even survive a hurricane.

What is true for all PV modules is that their power output naturally decreases with time by about 0.8% a year. It's called solar panel degradation. This is why most companies provide performance warranties, ensuring that the power output won't drop below a certain level in the future. With some brands like Silfab this warranty is issued for 30 years.

Illustrations – Marina Fionova

Article updated April 2024.

Find best solar panels at A1 SolarStore

We only work with trusted manufacturers and guarantee high-quality products.

Looking for “the One”: How to check the quality of a solar panel

Looking for “the One”: How to check the quality of a solar panel Second-hand solar panels: Are they worth it?

Second-hand solar panels: Are they worth it? What are Tier 1 solar panels and how to choose quality PV modules

What are Tier 1 solar panels and how to choose quality PV modules How to make solar panels and hurricanes tolerate each other

How to make solar panels and hurricanes tolerate each other